On Campus

This section highlights the academic projects I’ve worked on over the past two years at university, along with the extracurricular activities I’ve been actively involved in.

- Role: Team Member, Performance Analyst

Objective

Collaborated in a 5-member team to design a vehicle using pre-fabricated components, powered by a 2.5 kg falling weight, to travel 5 meters on a 5-degree inclined track. The goal was to reach the finish line in the shortest time.Key Contributions

- Component Sizing & Performance: Calculated optimal component sizes, focusing on performance factors such as wheel and gear ratios, to maximize the vehicle’s speed.

- Failure Analysis: Took the lead in writing the Failure Mode and Effects Analysis (FMEA) section of the report, identifying potential points of failure and proposing mitigation strategies.

- Collaboration & Execution: Worked closely with teammates on the report and actively participated in building sessions to ensure the vehicle was constructed effectively.

Outcome

Our team achieved 6th place in the entire cohort, demonstrating strong technical skills and teamwork.- Role: Student.

Objective

To gain hands-on experience in key manufacturing operations that will be essential in future engineering careers, including turning, milling, benchwork, and welding.

Key Contributions

These workshops are easily one of my favorite parts of the course, happening twice a year. I’ve already completed sessions on the lathe and welding, and can’t wait for the next round.

- Lathe Mastery: Designed and crafted a screw using a lathe machine, with guidance from expert staff, and learned the intricacies of precision turning.

- Welding Wizard: Practiced two different types of welding—Metal Inert Gas (MIG) and Tungsten Inert Gas (TIG)—honing skills in joining materials and understanding welding techniques.

- Safety First: Thoroughly reviewed and completed all required safety documentation before each session, ensuring safe and smooth operations in the workshops.

Learning

- Built practical skills in mechanical manufacturing methods, while also boosting confidence in working independently and in a team environment.

- Developed a deeper appreciation for hands-on work, particularly the precision and patience required in lathe and welding operations.

Objective

Design components using SolidWorks, convert them into STL files, and print them using an FDM 3D printer.

Key Contributions

Efficient Design Choice: Opted to design small, useful parts due to time constraints—specifically, four custom guitar picks with embedded designs.

SolidWorks Expertise: Created the designs efficiently, ensuring they were simple enough to meet the size and print limitations of the workshop.

Outcome

A few of the picks turned out great and ready to use, but the more detailed ones ended up brittle and resembled abstract art pieces.

Learning

Gained a solid understanding of the limitations of FDM printers, especially regarding the balance between design complexity and material strength.

Role: Wing Assembly Team

Objective

To contribute to the creation of the world’s largest quadcopter drone, built by the Giant Foamboard Aircraft Society (GFA) using foamboard—a cardboard-like material.

Key Contributions

Workshop Participation: Attended GFA’s “Build Days” workshops during the semester break and actively engaged in the assembly process.

Wing Work: Collaborated with other attendees to measure, cut, and glue together the massive wings, which were so large that solo assembly wasn’t an option.

Learning

Developed a better understanding of teamwork… and the complexities of aircraft wings, which are harder to put together than they look!

Exprimentation Zone!

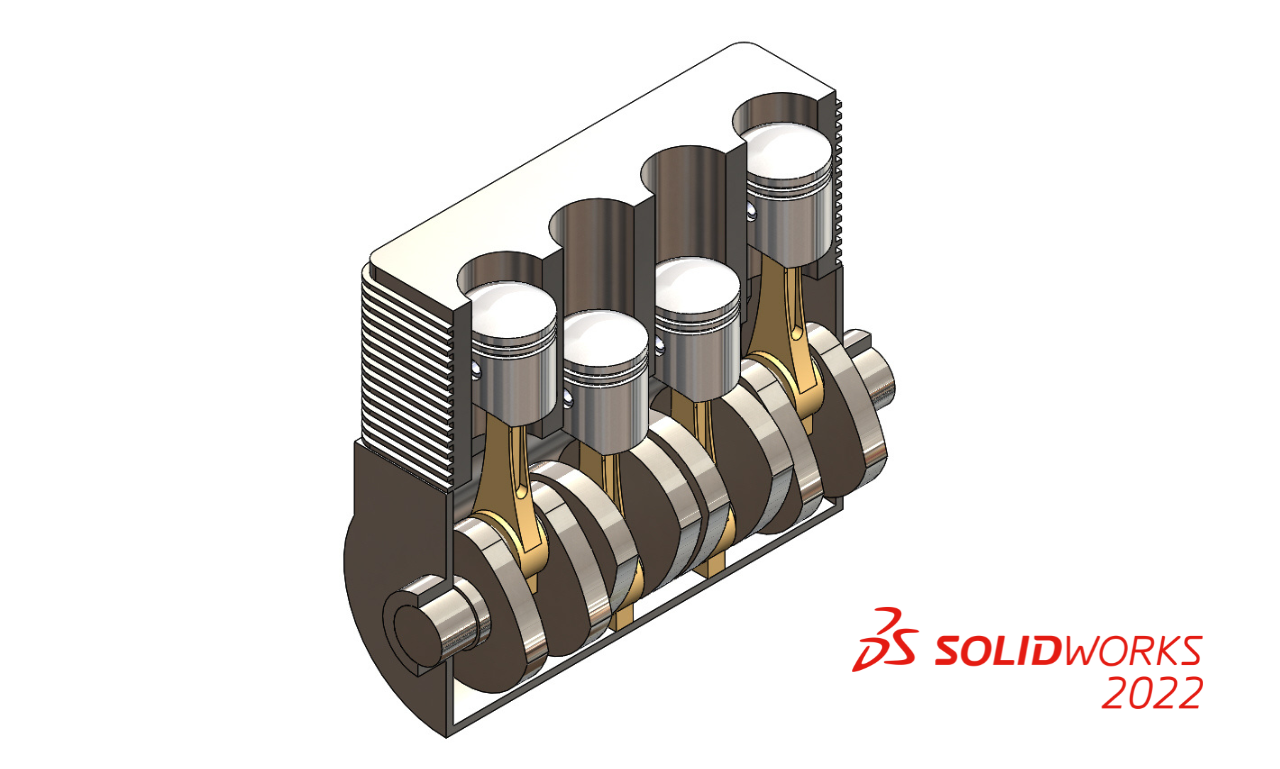

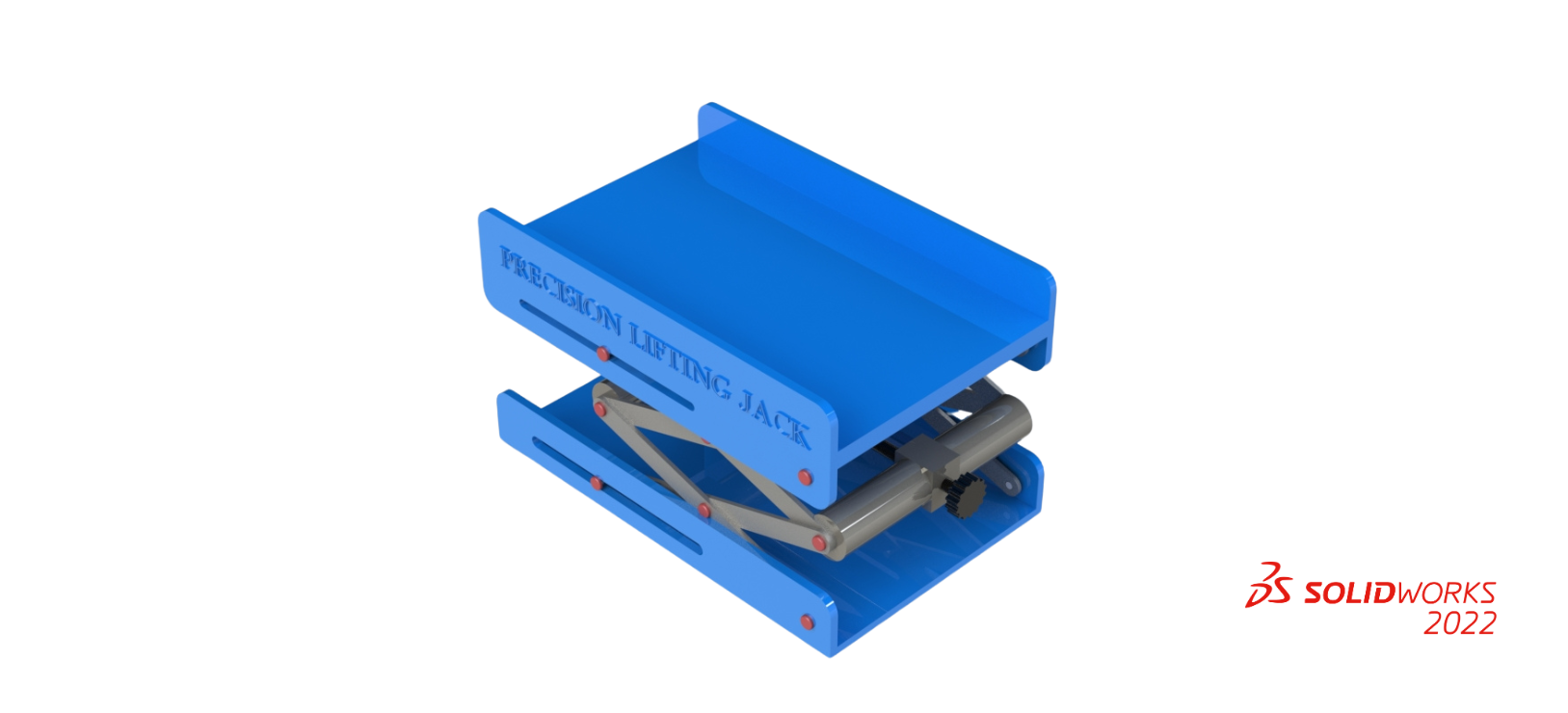

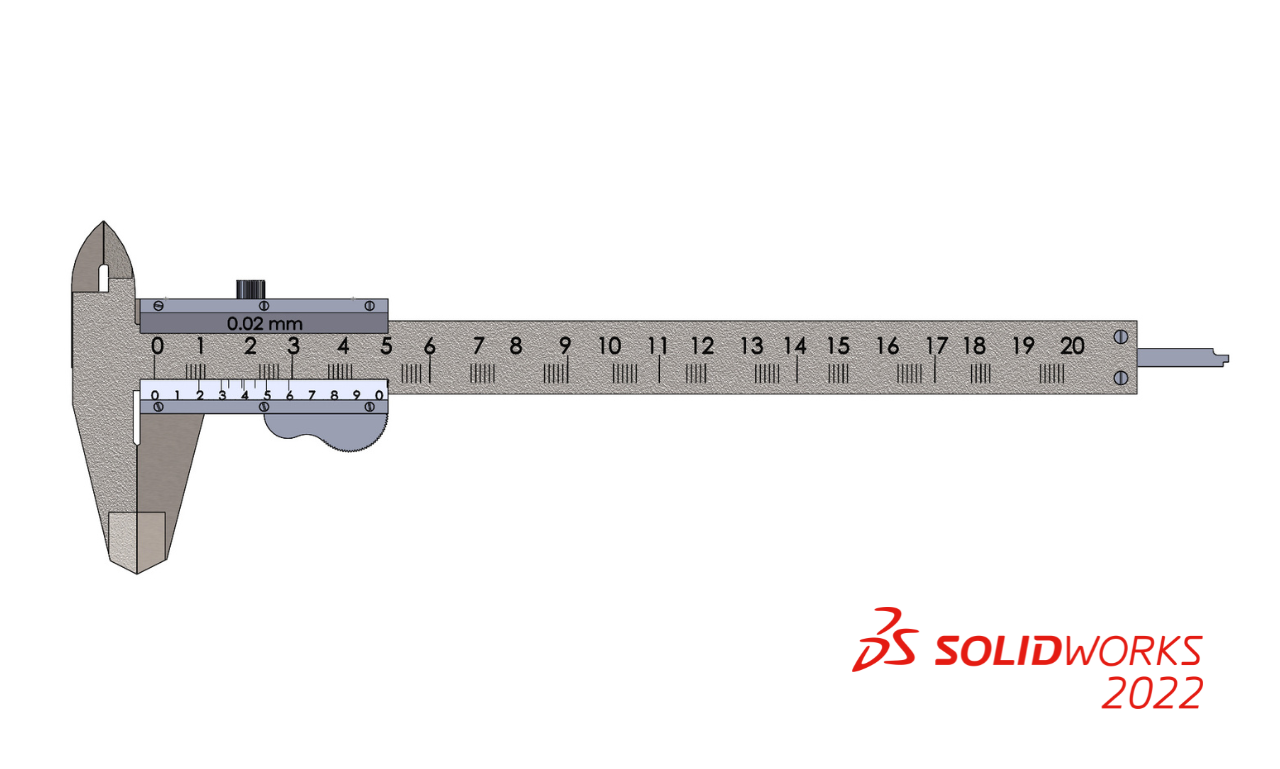

I was first introduced to SolidWorks in my very first year at university, and I found it genuinely interesting from the start. It quickly became one of my favourite creative tools. I enjoyed experimenting with it, mostly learning through YouTube tutorials and trying to sharpen my skills with each design.

At one point, I decided to give freelancing a try and set up a profile on Fiverr. Balancing freelance projects with university life and a part-time job turned out to be quite a challenge, so it didn’t last long. Still, it was a valuable experience that helped me build a small portfolio of designs.

Volunteering and Advocacy!

Much of this work builds on the experience and learning I gained as a sabbatical officer last year.

Click the button below to learn more about that role and my contribution.